In the changing world of modern manufacturing, being competitive requires more than just cutting-edge equipment and carefully considered processes.

In the manufacturing business, customer relationship management (CRM) systems, particularly CRM for manufacturing industry, have become indispensable for firms seeking to maximize their productivity.

A good CRM may improve communication, expedite procedures, and ultimately support excellence in manufacturing.

This post will discuss the important factors to take into account when selecting a CRM for the manufacturing sector and how it may benefit different aspects of the business.

Recognizing CRM’s Role in Manufacturing

A Manufacturing Contextual Definition of CRM

CRM is used in manufacturing for purposes other than just sales and marketing.

It becomes a crucial component of the whole plan, which includes dealing with customers, processing orders, managing the supply chain, and providing after-sale assistance.

A manufacturing-specific CRM system functions as a central repository of data, promoting cooperation and guaranteeing smooth communication throughout the value chain.

The Evolution of CRM in Manufacturing

The requirement for efficient CRM solutions has increased dramatically as industrial processes become more international and complicated.

The evolution of CRM in manufacturing, from legacy systems to cloud-based platforms, demonstrates the industry’s dedication to adjusting to shifting conditions and utilizing technology to drive long-term prosperity.

Important Things to Look for When Choosing a CRM for Manufacturing

1. Industry-Specific Customization

Different sectors have different manufacturing techniques, ranging from process manufacturing to discrete manufacturing. It’s critical to select a CRM system that enables customization for a certain sector. The CRM should integrate with specialist software, support specific data fields, and configure workflows to perfectly match the intricacies of the manufacturing industry.

2. Flexibility and Scalability

Variations in market dynamics, manufacturing quantities, and demand are continual challenges for manufacturers. To handle expansion, a CRM system has to be both adaptable and scalable. This includes being able to integrate with new modules, enlarge the user base, and adjust to new business models. This guarantees that the CRM will continue to be a useful tool as the manufacturing industry changes.

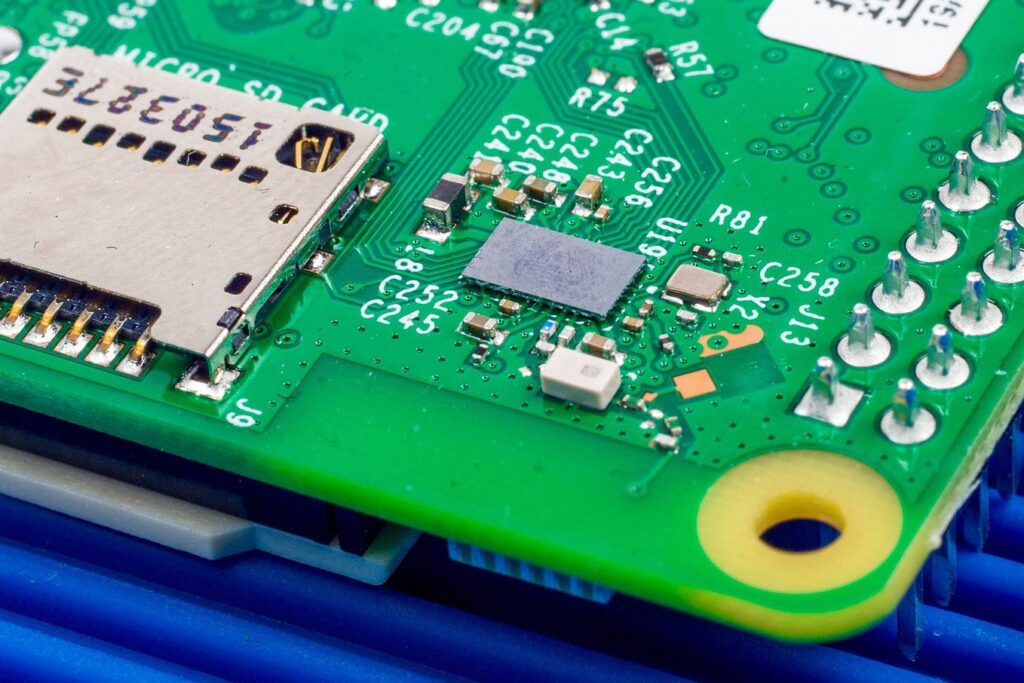

3. Integration Skills

CRM solutions must smoothly interface with current supply chain management tools, enterprise resource planning (ERP) systems, and other critical technologies to support manufacturing excellence. Intelligent decision-making at all organizational levels is made possible by integration, which optimizes data flow, reduces human input, and offers a comprehensive perspective of operations.

4. Interface That’s Easy to Use

The success of any CRM deployment in a manufacturing setting, when time is of importance, depends on user adoption. The system needs to include an easy-to-use interface that makes it easier for staff members in various departments to master new skills. An intuitive CRM facilitates quick and easy data entry and retrieval, freeing teams to concentrate on their primary duties.

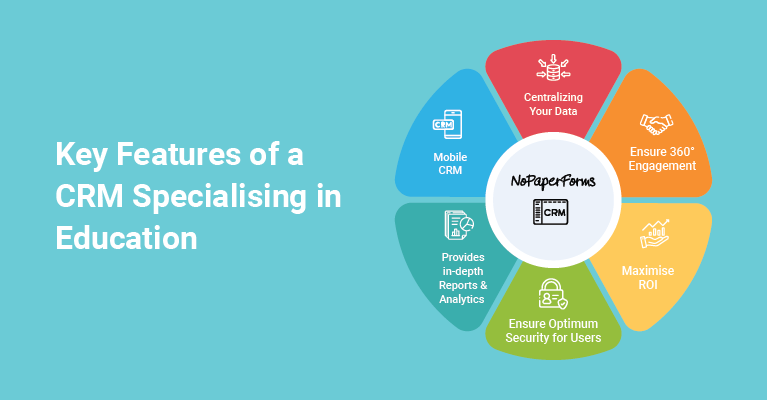

5. Accessibility on Mobile Devices

In a time when field operations and remote work are becoming more and more common, having a CRM with strong mobile accessibility is essential. Teams working in manufacturing should have mobile collaboration, real-time data access, and record-updating capabilities. Mobile CRM features improve productivity and communication by guaranteeing that important data is always accessible, wherever you are.

CRM’s effects on manufacturing excellence

1. Enhanced Communication with Clients

With the use of a well-designed CRM system, manufacturers may learn more about their customers. Manufacturers may tailor their products to meet customer expectations by tracking customer feedback, keeping an eye on purchase trends, and monitoring interactions. Stronger ties are established by this individualized approach, which increases client loyalty and repeat business.

2. Better Management of the Supply Chain

Excellent supply chain management is necessary to achieve industrial excellence. Users of CRM systems get access to information about all phases of the supply chain, including procurement, production, and distribution. Thanks to this insight, manufacturers can work with suppliers more efficiently, cut lead times, and maximize inventory levels—all of which help to create a lean and flexible supply chain.

3. Streamlined Methods of Production

CRM systems facilitate communication and collaboration among the several departments involved in the manufacturing process. When it comes to order processing and sales forecasting, unified CRM software ensures that everyone agrees. Streamlining production procedures, cutting down on errors, and raising general productivity, establishes the foundation for manufacturing excellence.

4. Data-Driven Decision Making

Every day, manufacturers work with enormous volumes of data. Decision-makers are empowered with actionable insights when a CRM system is fitted with strong analytics and reporting features. Manufacturers can drive operational excellence and continuous improvement by estimating future demand, recognizing trends, and evaluating past data to make well-informed decisions.

Conclusion

For manufacturing to be successful overall and to remain competitive, selecting the appropriate CRM for the manufacturing industry is essential.

Customization, scalability, integration, ease of use, and mobile accessibility are important components.

A CRM that is properly deployed improves supply chain management, expedites workflow, increases customer interaction, and facilitates data-driven decision-making.

Case studies from the real world demonstrate its revolutionary potential, increasing customer happiness and operational efficiency.

It’s critical to choose the correct vendor; take reputation, service, training, and total cost of ownership into account.

Essentially, including a good CRM for the manufacturing industry is a strategic investment in global manufacturing excellence rather than merely a technology update.