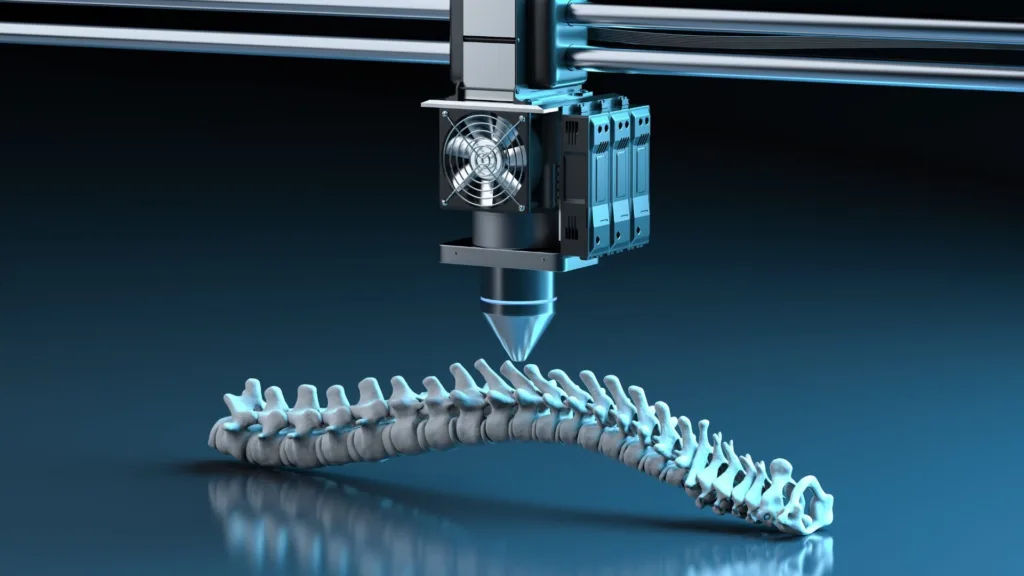

Imagine conjuring intricate objects from thin air, transforming digital dreams into tangible realities. That’s the magic of 3D printing, a technology rapidly evolving from futuristic fantasy to an accessible hobby and powerful industrial tool. So, you’re curious about embarking on this exciting journey? Buckle up, because we’re diving deep into the wondrous world of 3D printing!

What is 3D Printing?

In its essence, 3D printing, also known as additive manufacturing, brings digital designs to life. Unlike traditional sculpting or machining that removes material, this technology builds objects layer by layer, meticulously adding material until the desired form emerges. This opens doors to creating complex geometries and intricate designs often impossible with conventional methods.

A Spectrum of Wonders: Exploring Different 3D Printing Technologies

The world of 3D printing boasts a diverse array of technologies, each with its unique strengths and quirks. Here are some of the most common:

- Fused Deposition Modeling (FDM): The go-to choice for beginners, FDM printers melt plastic filament and extrude it layer by layer. They’re affordable, user-friendly, and offer a wide range of filament materials like PLA, ABS, and nylon.

- Stereolithography (SLA): Employing lasers to cure liquid resin layer by layer, SLA printers produce incredibly detailed and smooth prints with high resolution. However, they can be pricier and require more attention to safety and post-processing.

- Selective Laser Sintering (SLS): This industrial-grade technology uses lasers to sinter powdered materials like nylon or metal, creating robust and heat-resistant parts. However, the high cost and complex setup limit its accessibility for hobbyists.

Unveiling the Toolbox: Essential Equipment for Your 3D Printing Journey

Once you’ve chosen your printing technology, it’s time to gather your tools! Here’s a basic checklist:

- 3D Printer: The heart of your operation, select one that aligns with your budget, material preferences, and desired print quality.

- 3D Modeling Software: Design your creations with user-friendly options like Tinkercad or explore more advanced programs like Blender.

- Filament/Resin: Choose the material that suits your project’s needs, considering factors like strength, flexibility, and heat resistance.

- Safety Gear: Depending on your chosen technology, invest in safety glasses, gloves, and proper ventilation for fume control.

- Basic Tools: Pliers, tweezers, and a craft knife come in handy for post-processing and support removal.

From Pixels to Print: The 3D Printing Workflow

Now, let’s embark on the exhilarating process of bringing your ideas to life:

- Design: Imagine and create your 3D model using software. Start with simple shapes and progress to more complex designs as you gain experience.

- Slice: Prepare your model for printing by converting it into thin layers that the printer can understand. Slicing software helps achieve this with various settings to optimize your print.

- Print: Load your sliced file onto your printer and watch in awe as your digital design materializes layer by layer. Printing time can vary depending on the object’s size and complexity.

- Post-Processing: Depending on the technology, remove support structures, sand smooth any rough surfaces, and apply paint or finishes for a personalized touch.

A Universe of Possibilities: Applications of 3D Printing

The potential applications of 3D printing are vast and ever-expanding, reaching across industries and igniting creativity:

- Prototyping: Quickly and affordably create physical models for product development, testing, and iteration.

- Manufacturing: Produce custom parts, tools, and jigs on-demand, reducing reliance on traditional manufacturing processes.

- Education: Facilitate hands-on learning in STEM fields by allowing students to visualize and create complex 3D models.

- Art and Design: Sculpt unique jewelry, figurines, and functional art pieces, pushing the boundaries of artistic expression.

- Medical applications: Create custom prosthetics, implants, and even bioprinted tissues for personalized medical care.

Embracing the Community: Resources and Support

As you begin your 3D printing journey, remember, you’re not alone! Here are some valuable resources to tap into:

- Online Communities: Join forums, groups, and social media channels dedicated to 3D printing to connect with other enthusiasts, share experiences, and seek advice.

- Libraries and Makerspaces: Many libraries and community centers offer 3D printing services and workshops, providing access to printers and guidance for beginners.

- Online Learning Platforms: Explore online courses and tutorials to deepen your understanding of 3D modeling, printing techniques, and best practices.

Frequently Asked Questions About 3D Printing

So, you’re intrigued by the world of 3D printing, but a few lingering questions hold you back? Worry not, aspiring maker! Here’s a breakdown of some commonly asked questions, equipping you with the knowledge to confidently embark on your 3D printing adventure:

How much does a 3D printer cost?

3D printers range in price, catering to various budgets. Beginner-friendly FDM printers can start around $200, while professional-grade machines can reach thousands. Consider your needs and prioritize features most relevant to your projects.

Is 3D printing difficult to learn?

The learning curve depends on your chosen technology and desired complexity. FDM printing with user-friendly software is relatively beginner-friendly. As you delve into more advanced technologies and intricate designs, be prepared to invest time and effort in honing your skills.

What are the safety concerns with 3D printing?

Some technologies, like SLA printing, involve fumes and require proper ventilation and protective gear. Always follow safety guidelines specific to your chosen technology and materials.

Where can I find 3D models to print?

Numerous online repositories like Thingiverse offer free and paid 3D models. Alternatively, design your own models using 3D modeling software.

What are the environmental implications of 3D printing?

While some materials are more eco-friendly than others, responsible material selection and proper waste disposal are crucial for minimizing environmental impact.

What are the limitations of 3D printing?

Currently, print size and material options have limitations. Additionally, achieving ultra-fine details might require advanced technologies. However, 3D printing technology is constantly evolving, pushing these boundaries further.

Stepping into the realm of 3D printing unlocks a world of creative possibilities and problem-solving potential. Embrace the learning journey, tap into the supportive community, and remember, the most important ingredient is your own curiosity and desire to explore. Now, go forth and unleash your inner maker! The world awaits your unique 3D printed creations.